Unleash Your Creativity: The Sticker Making Process

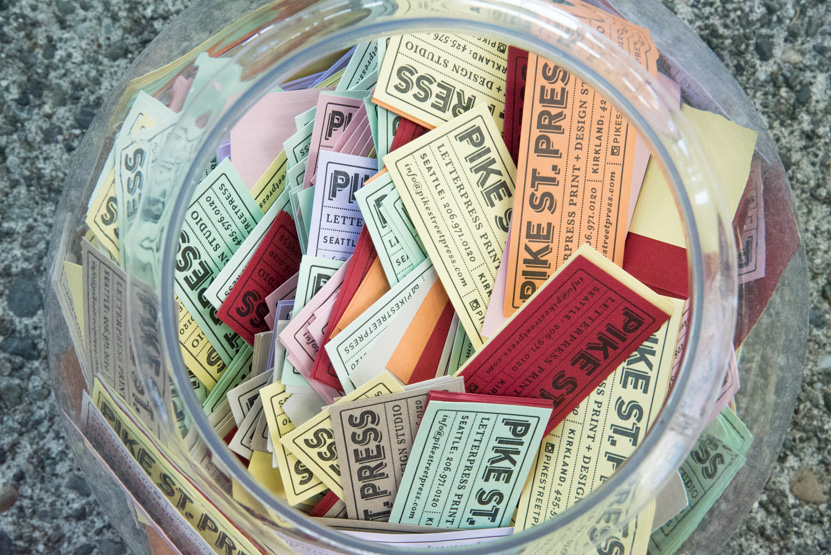

How Stickers Are Made at Pike Street Press

Ever wondered how those fun little stickers come to life? At Pike Street Press, we’re here to break down the sticker-making process into simple steps, so you can appreciate these sticky wonders even more. Let’s dive in!

The Sticker-Making Process

Creating a sticker might seem straightforward, but there’s a bit of art and science behind it. Here’s how we do it at Pike Street Press.

Step 1: Designing the Artwork

- Function: What is the function of your design? is it going on your Subaru? water bottle? or ski's? How it is used in the wild, will influence how the design is created. You may want something simple for distance or detailed for close encounters.

- Choose Good Colors: Depending on what your going for use colors that work well together or colors that stand out against each other. Brights on dark backgrounds work wonders! Here is an article that outlines color theory.

- Keep It Simple: A clean design is easier to see from a distance. Avoid clutter! it is all about perception and style.

- Pick Durable Materials: If your sticker is going outside, choose materials that can handle the weather. Adhesive strength, ink type and lamination will influence final results. Quality materials = Quality product.

Step 2: Printing the Stickers

Once the design is ready, it’s time to print. We use a digital Roland printer to transfer your artwork onto white adhesive vinyl. This special vinyl has a sticky back that you can peel off and stick onto just about anything. (it's permanent) After printing, we check each sticker for quality and remove any that don’t meet our standards. We ensure no blemishes, colors match, and quantities are suitable.

Step 3: Laminating for Durability

To make your stickers last longer, we apply a protective layer called laminate. This helps prevent fading, scratching, and other wear and tear, especially for stickers that will be used outdoors. You can choose from glossy, matte, or textured finishes, depending on your style! We use the matte finish 3 mil, creating a 6mil sticker.

Step 4: Cutting to Shape

Now that your stickers are printed and laminated, it’s time to cut them into the desired shape. We use various cutting methods, such as:

- Die-Cutting/ Perforation Cut: Using little metal blades to cut out the entire sticker into a specific shapes. This is a majority of our 6mil stickers.

- Kiss-Cutting/ Contour Cut: Leaving extra material around the sticker for easier peeling.Usually for a label or unlaminated 3 mil sheet sticker.

All of this is done on a Roland Plotter.

Step 5: Application

Finally, it’s time to apply the stickers! Just peel off the backing and stick them on a clean, dry surface. Here’s how to do it right:

- Prep the Surface: Make sure it’s clean and dry. We prefer a cleaner that evaporates and wont leave a residue.

- Apply Slowly: Work from one corner and move across to avoid air bubbles or wrinkles.

- Avoid Direct Sunlight: Stickers adhere best away from harsh sunlight and extreme temperatures.

- Let the bond happen: let the sticker adhesive do its thing by bonding over the next 36-48hrs.

Frequently Asked Questions (FAQs)

What materials are used to make stickers?

Stickers can be made from various materials, including paper, vinyl, and polypropylene. Each has its advantages, like durability and resistance to the elements. We us vinyl with a paper backing, which after printing is laminated.

How long do stickers last?

The lifespan of a sticker depends on its material and where and how it’s used. Laminated stickers used outdoors can last for years (3-5+), while paper or un-laminated stickers may fade quicker.

Can I design my own stickers?

Absolutely! You can create your own designs using design software (like Procreate) or even sketch them by hand. Just make sure they’re converted to a digital format before sending to us for printing.

Do you offer custom sticker sizes?

Yes! At Pike Street Press, we can produce stickers in various shapes and sizes to fit your needs. We like the iPhone test, if it fits on the back of the iPhone its generally a good size. But we have a 54" wide printer so anything less is usually do-able.

How can I promote my business with stickers?

Custom stickers are a fantastic way to market your business. Hand them out at events, use them on packaging, or put them on company vehicles to get your brand noticed!

Conclusion

Now that you know how stickers are made, you can appreciate the creativity and effort that goes into each one. Whether you’re looking to design your own stickers or simply enjoy using them, we hope this guide has inspired you. If you have any questions or want to create your own custom stickers, reach out to us at Pike Street Press! We’d love to help bring your ideas to life.

This project was for Roam Vacation Rentals. Check them out here.

PS: All of our vinyl and laminate is made in the USA